An Scientific Approach of Design and Development of a Garlic Peeling Machine

Keywords:

Garlic peeling machine, Garlic peel, Garlic skinAbstract

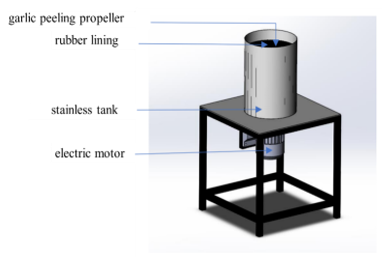

Garlic, a species of bulbous flowering plant commonly eaten fresh, can be processed into a wide variety of products. One of these is peeled garlic, which is gaining in popularity among consumers as it offers convenience to many who wish to escape the hassle of garlic peeling. Therefore, the objectives of the present study was to develop an affordable garlic peeling machine that could efficiently increase processing capacity and reduce processing time as well as to assess its operational performance. To that end, a garlic peeling machine with the dimensions of 50 cm in width, 50 cm in length, and 85 cm in height was constructed that comprised a base, a tank having a diameter of 26 cm and a height of 35 cm which was lined with a durable rubber sheet, and a garlic peeling propeller. Installed under the tank to drive the propeller was a 3-phase electric motor. The material used to measure the efficiency of the machine was Chinese garlic bulbs weighing 200 and 300 g with a moisture content (wet basis) of 64.31%, and the machine efficiency was evaluated across the motor speeds of 450, 550, and 650 rpm and the processing intervals of of 10, 20, and 30 s. The results showed that no matter whether the test material weighed 200 or 300 g, the highest peeled garlic yield was obtained with the motor speed of 650 rpm and the processing interval of 20 s with the weight of intact garlic and damaged garlic combined standing at 179.5 g, or 89.76% of the total garlic weight, and 230.86 g, or 76.95% of the total garlic weight, respectively. In comparison, no matter whether the test material weighed 200 or 300 g, the highest intact garlic yield was achieved with the motor speed of 650 rpm and the processing interval of 10 s with the weight of intact garlic equaling 81.28 g, or 40.64% of the total garlic weight, and 53.56 g, or 17.85% of the total garlic weight, respectively.

Downloads

References

Agricultural Research Development Agency (Public Organization)."Garlic." https://www.arda.or.th/kasetinfo/north/plant/garlic.html (accessed July 2, 2022 ).

Department of Agriculture. "Current situation of garlic." https://www.doa.go.th/hort/wp-content/uploads/2020/07/A1-63.pdf (accessed June 02, 2022).

Office of Agricultural Economics. "Garlic." http://mis-app.oae.go.th/product/%E0%B8%81%E0%B8%A3%E0%B8%B0%E0%B9%80%E0%B8%97%E0%B8%B5%E0%B8%A2%E0%B8%A1 (accessed July 2, 2022)

T. Peebkhunthod, "Development and construction of a garlic peeling machine," Master's degree, Department of Mechanical Engineering, Faculty of Engineering, Mahasarakham University, Thailand, 2016.

Y. Haelerttrakul, "A study of basic factors in creating a simple garlic peeling machine," (in Thai), Vocational Education Central Region Journal, vol. 2, no. 1, pp. 26-33, 2018.

A. Chirattiyangkur and A. Mongkolthalaeng, "A manual garlic clove peeling machine," (in Thai), Kasetsart Engineering Journal, vol. 21, no. 65, pp. 70-78, 2008

W. Kaewka and A. Srichart, "Development of a garlic peeling machine using circulating air pressure," (in Thai), Farm Engineering and Automation Technology Journal of Food Engineering, vol. 4, no. 1, pp. 1-8, 2018.

M. Manjunatha, D. V. K. Samuel, R. K. Anurag, and N. Gaikwad, "Development and performance evaluation of a garlic peeler," Journal of Food Science and Technology, vol. 51, no. 11, pp. 3083–3093, 2014, doi: 10.1007/s13197-012-0879-5

S. N. Singh, S. K. Vekariya, P. S. Pandit, F. M. Sahu, and R. G. Burbad, "Design and development of a rotary disc type garlic clove peeling machine," CIGR Journal, vol. 24, no. 1, pp. 228-238, 2022.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Virat Whangkuanklang, Yongyuth Siangdang, Mongkolchai Kampagdee, Purin Akkarakultron, Suwonnakan Supamattra, Khongdet Phasinam, Dowroong Watcharinrat

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

All papers should be submitted electronically. All submitted manuscripts must be original work that is not under submission at another journal or under consideration for publication in another form, such as a monograph or chapter of a book. Authors of submitted papers are obligated not to submit their paper for publication elsewhere until an editorial decision is rendered on their submission. Further, authors of accepted papers are prohibited from publishing the results in other publications that appear before the paper is published in the Journal unless they receive approval for doing so from the Editor-In-Chief.

IJISAE open access articles are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License. This license lets the audience to give appropriate credit, provide a link to the license, and indicate if changes were made and if they remix, transform, or build upon the material, they must distribute contributions under the same license as the original.