Energy Monitoring of Process Variables and Optimization of Nozzle Section in Sustainable Plastic Injection Molding

Keywords:

Plastic Injection Molding (PIM), Energy Monitoring, Optimized Nozzle Selection, CATIA and MATLABAbstract

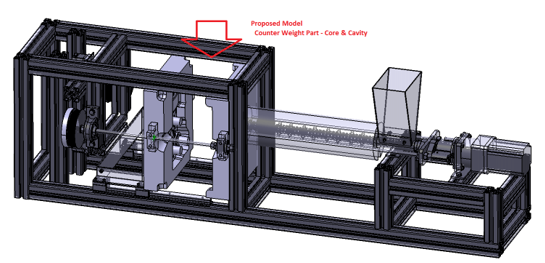

With respect to the improvement of energy monitoring and optimized nozzle section in Sustainable Plastic Injection Molding (EMONS-PIM) to achieve the Cost-Effective end product for the industries. During the process of molding of Polymethyl Methacrylate (PMMA) the effects of parameters in terms of energy consumption needs to get determined. Energy efficiency is a severe issue because of the increasing energy costs as well as the correlated environmental impact. The major parameters which are concentrated in terms of energy are melting and molding temperature, holding and cooling time, screw rotational speed and nozzle temperature. The highest impact on energy consumption is produced by cooling time and nozzle temperature. Simulation is done among the process parameters and the equivalent energy dissipation is recorded at each instant of time. Several hydraulic injection molding machines are considered for energy monitoring process and found out the energy saving opportunities. The optimization of nozzle section and energy monitoring is simulated using the software’s CATIA and MATLAB. In CATIA the effective nozzle section is performed and the relevant analysis is performed. In MATLAB the process of energy consumption reduction is concentrated and the parameters which are considered for the process of simulation analysis are sum rate, bit error rate, convergence plot and energy consumption. The materials which are considered in the PIM process are thermoplastic polystyrene, thermoplastic acrylonitrile butadiene styrene and thermoplastic polyvinyl chloride. To perform the process of comparative analysis the end results of the proposed EMONS-PIM method is compared with the earlier researched like AntLion Optimization, PSO-MSQPA and MLGS-PIM.

Downloads

References

Ramorino, G., Agnelli, S. and Guindani, M., “Analysis of Reactive Injection Compression Molding by Numerical Simulations and Experiments”, Advances in Polymer Technology, vol. 2020, 2020,pp. 1-8, doi: 10.1155/2020/1421287.

Langheck, A., Reuter, S., Saburow, O., Maertens, R., Wittemann, F., Berg, L.F. and Doppelbauer, M., “Evaluation of an integral injection molded housing for high power density synchronous machines with concentrated single-tooth winding”, International Electric Drives Production Conference (EDPC), vol. 8, 2018, pp. 1-6, doi: 978-1-7281-0148-4/18

Dhutekar, P., Mehta, G., Modak, J., Shelare, S. and Belkhode, P., “Establishment of mathematical model for minimization of human energy in a plastic moulding operation”, Materials Today: Proceedings, vol. 47, pp. 4502-4507, doi: 10.1016/j.matpr.2021.05.330.

Kumar, B.P., Venkataramaiah, P. and Ganesh, J.S., “Optimization of process parameters in injection moulding of a polymer composite product by using gra”, Materials Today: Proceedings, vol. 18, 2019, pp.4637-4647.

He, W., Yang, J., Chen, Y., Liu, P., Li, C., Xiong, M., Niu, X. and Li, X., “Study on co-injection molding of poly (styrene-ethylene-butylene-styrene) and polypropylene: Simulation and experiment”, Polymer Testing, vol. 108, 2022, p.107510, doi: 10.1016/j.polymertesting.2022.107510

Finkeldey, F., Volke, J., Zarges, J.C., Heim, H.P. and Wiederkehr, P., “Learning quality characteristics for plastic injection molding processes using a combination of simulated and measured data. Journal of Manufacturing Processes, vol. 60, 2020, pp.134-143, doi: 10.1016/j.jmapro.2020.10.028.

Kvaktun, D., Hoffmann, A. and Schiffers, R., “Analysis of feature extraction algorithms for quality prediction using machine learning in injection molding”, Procedia CIRP, vol. 112, 2022, pp. 590-595, doi: 10.1016/j.procir.2022.09.059

Fan, Z., Gao, R.X. and Kazmer, D.O., “Self-energized acoustic wireless sensor for pressure-temperature measurement in injection molding cavity”, In SENSORS, 2009 , pp. 65-68, doi: 978-1-4244-5335-1/09

Fauzun, I., Hamdi, M., Tontowi, A.E. and Ariga, T., “Formulation of the size and position of spiral cooling channel in plastic injection mold based on fluent simulation results”, International Conference on Industrial Engineering and Engineering Management, 2008, pp. 1728-1733, doi:9 78-1-4244-2630-0/08

Peng, H.S., Huang, P.W., Liew, K.F., Chien, P.C. and Su, W.J., “Study of CAE predictive analytics on structure design, molding and improved strength of plastic injection molded parts”, International Conference on Applied System Innovation (ICASI), 2017, pp. 546-549, doi: 78-1-5090-4897-7

Jiao, Z., Yang, W., Xie, P. and Wang, X., “Automatic control and energy-saving mechanism of internal circulation two-platen injection molding machine”, International Conference on Mechanic Automation and Control Engineering, 2010, pp. 5491-5494, doi:9 78-1-4244-7739-5/10

Mianehrow, H. and Abbasian, A., “Energy monitoring of plastic injection molding process running with hydraulic injection molding machines”, Journal of Cleaner Production, vol. 148, 2017, pp.804-810, doi: /10.1016/j.jclepro.2017.02.053

Meekers, I., Refalo, P. and Rochman, A., “Analysis of process parameters affecting energy consumption in plastic injection moulding. Procedia CIRP, vol. 69, 2018, pp.342-347, doi:

Tranter, J.B., Refalo, P. and Rochman, A., “Towards sustainable injection molding of ABS plastic products”, Journal of Manufacturing Processes, vol. 29, 2017, pp.399-406, doi: 10.1016/j.jmapro.2017.08.015

Hernandez, L.O., Negussie, H., Mazzola, L.T., Laser, D.J. and Droitcour, A., “Integrated heaters for temperature control in disposable bioassay cartridges for use with portable, battery-operated instruments”, International Conference of the IEEE Engineering in Medicine and Biology Society, 2017, pp. 326-332, doi: 978-1-4244-4122-8/11

Villarreal-Marroquín, M.G., Cabrera-Ríos, M. and Castro, J.M., “A multicriteria simulation optimization method for injection molding”, In Proceedings of the 2011 Winter Simulation Conference (WSC), 2011, pp. 2390-2402, doi: 978-1-4577-2109-0/11

Wang, S., Ying, J., Chen, Z. and Feng, Y., “Packing pressure control for energy-saving servo injection molding based on Fuzzy-PID controller”, International Conference on Mechanical and Electronics Engineering, vol. 1, 2010, pp. V1-34, doi: 978-1-4244-7481-3

Gurel, B., Osman, I.P.E.K., Basogul, Y. and Kecebas, A., “Optimization of Nozzle Section in Plastic Injection Moulding Process”, Hittite Journal of Science and Engineering, vol. 6, no. 2, 2019, pp.123-130, doi: 10.17350/HJSE19030000137

Kumara, H.A. and Babu, K.R., “Improvement in production rate for 3 phase energy meter terminal block by choosing an optimum gate location and reducing the defects of the tool”, In National Conference on Challenges in Research & Technology in the Coming Decades , vol. 2013, 2013, pp. 1-5, doi:

Downloads

Published

How to Cite

Issue

Section

License

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

All papers should be submitted electronically. All submitted manuscripts must be original work that is not under submission at another journal or under consideration for publication in another form, such as a monograph or chapter of a book. Authors of submitted papers are obligated not to submit their paper for publication elsewhere until an editorial decision is rendered on their submission. Further, authors of accepted papers are prohibited from publishing the results in other publications that appear before the paper is published in the Journal unless they receive approval for doing so from the Editor-In-Chief.

IJISAE open access articles are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License. This license lets the audience to give appropriate credit, provide a link to the license, and indicate if changes were made and if they remix, transform, or build upon the material, they must distribute contributions under the same license as the original.