Corrosion Detection and Prediction for Underwater pipelines using IoT and Machine Learning Techniques

Keywords:

Underwater pipelines, semi-supervised machine learning, feature extraction and feature selection, internet of things, cloud databaseAbstract

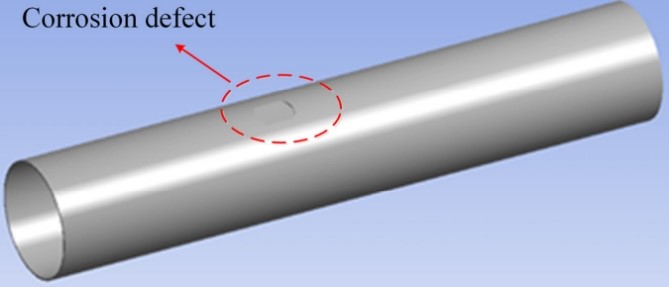

Pipelines are commonly utilized to transmit chemical fluids over thousands of kilometres all over the globe. The pipes are designed to withstand a variety of environmental loading conditions, providing safe and durable delivery from the manufacturing location to the coast or distribution station. Leaks in piping systems, on the other side, are among the primary causes of numerous damages for pipeline operators and the surroundings. Pipeline failures may cause significant environmental catastrophes, human deaths, and financial losses. Significant research has been devoted to corrosion and localization using alternative strategies to avoid this threat and preserve an efficient and proper transmission infrastructure. This paper proposed a corrosion detection and prediction system using Internet of Things (IoT) and machine learning techniques. The system collaborates with two different methodologies, such as IoT utilized to collect data from underwater pipelines and various learning algorithms to identify corrosion possibilities. We have used analogue sensors such as thickness, GPS, pH, etc., to capture the current event. Based on pH value, impact of pipe thickness for a specific period has been analysed depending on learning algorithm. The standard defines policy rules and has used a semi-supervised learning algorithm for validation. The Q-learning based classification algorithm generates reward and penalty for each event and, based on that, defines the possibility of corrosion. A variety of extraction of features and selection methods were used during this research using the IoT model. An extensive experiment analysis of the proposed algorithm obtains higher classification and detection accuracy over the traditional machine learning classification algorithms.

Downloads

References

. Kandiyoti, R. Under the sea. Eng. Technol. 2009, 4, 26–28.

. Shama, A.M.; Bady, A.; El-Shaib, M.N.; Kotb, M.A. Review of leakage detection methods for subsea pipeline. In Proceedings of the 17th International Congress of the International Maritime Association of the Mediterranean, Lisbon, Portugal, 9–11 October 2017.

. Veritas, N.D. Selection and Use of Subsea Leak Detection Systems. Recommended Practice Det Norske Veritas DNV-RP-F302, Veritasveien, Norway. 2010.

. Brunone, B. Transient test-based technique for leak detection in outfall pipes. J. Water Resour. Plan. Manag. 1999, 125, 302–306.

. Meniconi, S.; Capponi, C.; Frisinghelli, M.; Brunone, B. Leak Detection in a Real Transmission Main Through Transient Tests: Deeds and Misdeeds. Water Resour. Res. 2021, 3, e2020WR027838.

. Murvay, S.P.; Silea, I. A survey on gas leak detection and localization techniques. J. Loss Prev. Process Ind. 2012, 6, 966–973.

. Mahmutoglu, Y.; Kadir, T. Received signal strength difference-based leakage localization for the underwater natural gas pipelines. Appl. Acoust. 2019, 153, 14–19.

. Adegboye, A.M.; Fung, W.K.; Karnik, A. Recent advances in pipeline monitoring and oil leakage detection technologies: Principles and approaches. Sensors 2019, 11, 2548.

. Zemel, R.S. A Gradient-Based Boosting Algorithm for Regression Problems. In Proceedings of the 13th International Conference on Neural Information Processing Systems, Hong Kong, China, 3–6 October 2006

. Boaz, L.; Kaijage, S.; Sinde, R. An overview of pipeline leak detection and location systems. In Proceedings of the 2nd Pan African International Conference on Science, Computing and Telecommunications (PACT 2014), Arusha, Tanzania, 14–18 July 2014; IEEE: Piscataway, NJ, USA, 2014.

. Jia, Z.; Ren, L.; Li, H.; Sun, W. Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network. Appl. Sci. 2018, 8, 146.

. Manekiya, M.H.; Arulmozhivarman, P. Leakage detection and estimation using IR thermography. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1516–1519.

. Recommended, Practice. DNVL-RP-F302—Edition April 2016. Available online: https://rules.dnvgl.com/ docs/pdf/DNVGL/RP/2016-04/DNVGL-RP-F302.pdf (accessed on 15 February 2019).

. Datta, S.; Sarkar, S. A review on different pipeline fault detection methods. J. Loss Prev. Process Ind. 2016, 41, 97–106.

. Ai, C.; Zhao, H.; Ma, R.; Dong, X. Pipeline damage and leak detection based on sound spectrum LPCC and HMM. In Proceedings of the Sixth International Conference on Intelligent Systems Design and Applications (ISDA’06), Jinan, China, 16–18 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 829–833.

. Bradford, J.H.; Dickins, D.F.; Brandvik, P.J. Assessing the potential to detect oil spills in and under snow using airborne ground-penetrating radar. Geophysics 2010, 75, 1–12.

. Jasper, A. Oil/Gas Pipeline Leak Inspection and Repair in Underwater Poor Visibility Conditions: Challenges and Perspectives. J. Environ. Prot. 2012, 3, 394–399.

. Chris, T. Subsea Leak Detection; Neptune Oceanographics Ltd.: Carlbury, UK, 2007.

. Park, G.; Cudney, H.H.; Inman, D.J. Feasibility of using impedance-based damage assessment for pipeline structures. Earthq. Eng. Struct. Dyn. 2001, 30, 1463–1474.

. Anisi, D.A.; Skourup, C. A step-wise approach to oil and gas robotics. In Proceeding of the 2012 IFAC workshop on Automatic Contral in offshore oil and gas production, Trondheim, Norway, 31 May–1 June 2012; Volume 45, pp. 47–52.

. Gómez, C.; Green, D.R. Small unmanned airborne systems to support oil and gas pipeline monitoring and mapping. Arab. J. Geosci. 2017, 10, 202–209.

. Nguyen, T.C.; Huynh, T.C.; Ryu, J.Y.; Park, J.H.; Kim, J.T. Bolt-loosening identification of bolt connections by vision image-based technique. In Proceedings of the SPIE 9804, Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, Las Vegas, NV, USA, 8 April 2016.

. Park, J.H.; Huynh, T.C.; Choi, S.H.; Kim, J.-T. Vision-based technique for bolt-loosening detection in wind turbine tower. Wind Struct. 2015, 21, 709–726.

. Wang, C.; Wang, N.; Ho, M.; Chen, X.; Song, G. Design of a New Vision-based Method for the Bolts Looseness Detection in Flange Connections. IEEE Trans. Ind. Electron. 2019, in press.

. Saikat Bose, Tripti Arjariya, Anirban Goswami, Soumit Chowdhury Multi-Layer Digital Validation of Candidate Service Appointment with Digital Signature and Bio-Metric Authentication Approach International Journal of Computer Networks & Communications (IJCNC) Vol.14, No.5, September 2022 DOI: 10.5121/ijcnc.2022.14506

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vaibhav A. Parjane, Tripti Arjariya, Mohit Gangwar

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

All papers should be submitted electronically. All submitted manuscripts must be original work that is not under submission at another journal or under consideration for publication in another form, such as a monograph or chapter of a book. Authors of submitted papers are obligated not to submit their paper for publication elsewhere until an editorial decision is rendered on their submission. Further, authors of accepted papers are prohibited from publishing the results in other publications that appear before the paper is published in the Journal unless they receive approval for doing so from the Editor-In-Chief.

IJISAE open access articles are licensed under a Creative Commons Attribution-ShareAlike 4.0 International License. This license lets the audience to give appropriate credit, provide a link to the license, and indicate if changes were made and if they remix, transform, or build upon the material, they must distribute contributions under the same license as the original.